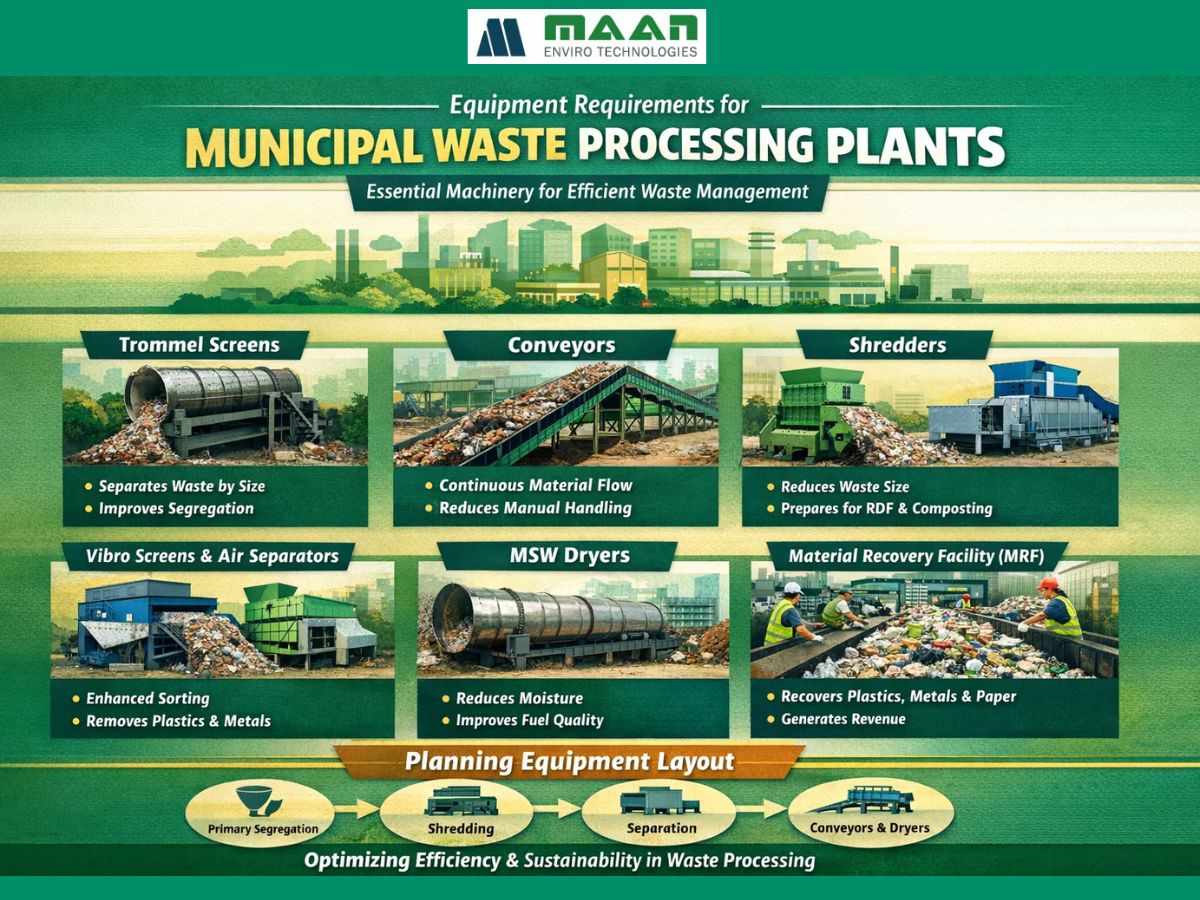

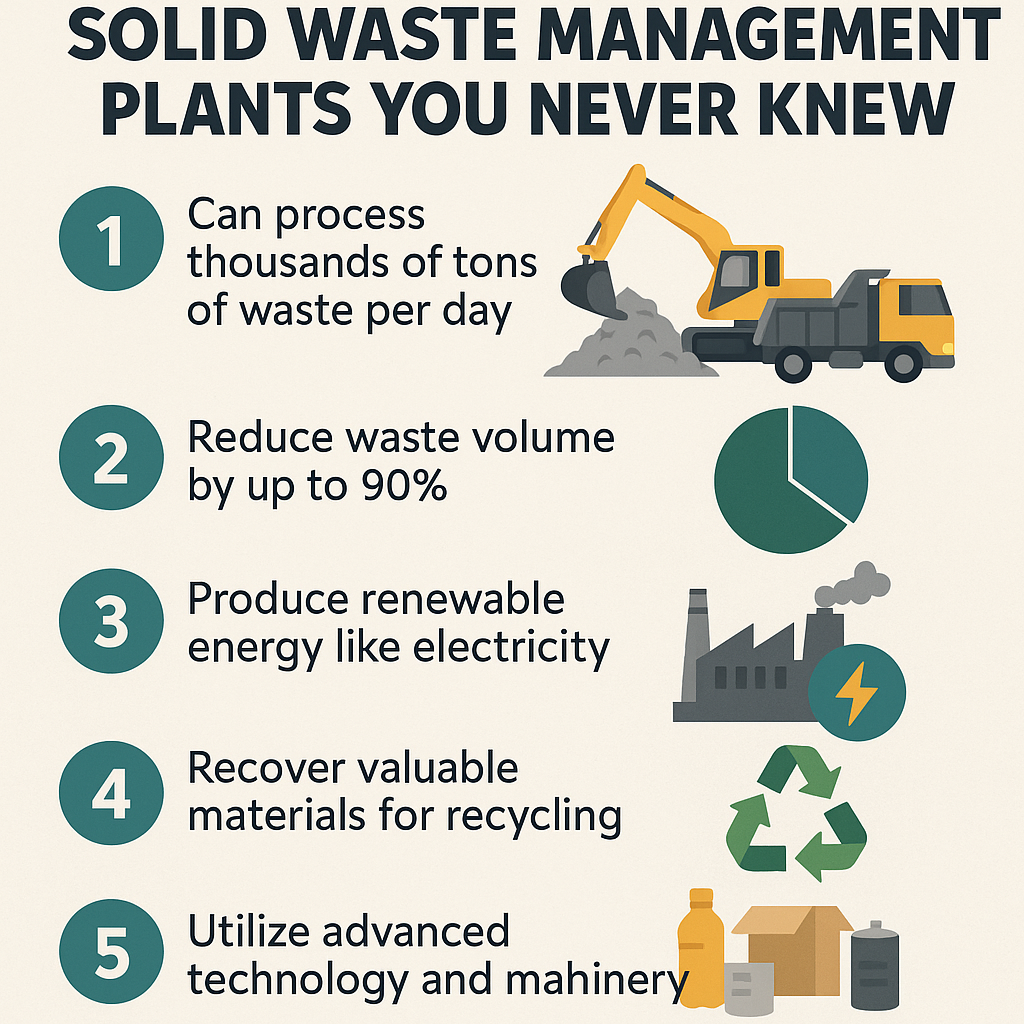

A trommel machine is a rotating cylindrical screen used to separate waste materials based on size. It helps in sorting mixed waste into different categories like organic matter, plastics, sand, metals, and other dry waste. This simple process supports cleaner, faster, and more organised waste segregation in solid waste management systems.

The machine works by feeding waste into a rotating drum. As the drum turns, smaller particles pass through perforated screens while larger ones are carried forward. This helps reduce manual sorting and prepares waste for further processing like composting, recycling, or RDF production.

Many municipal bodies and private contractors rely on rotary screen machines in India for daily waste segregation. These machines are commonly used in municipal solid waste plants, composting facilities, and legacy waste sites. They are often referred to as drum screeners or trommel separators and are built to handle different types of Indian waste, including mixed household and market waste.

Rotary screens improve processing speed, reduce labour costs, and minimise cross-contamination between waste streams. Their simple design also makes them easy to operate and maintain, even in demanding conditions.

For more detailed insight into how these machines are used in larger systems, see The Role of Trommel Screen Machines in Modern Waste Management Systems, which explores their place in today’s waste handling practices.

With the growing need for efficient waste handling, trommel machines continue to play a vital role in keeping segregation clean, systematic, and scalable across urban and industrial settings.

Write a comment ...