Setting up a municipal solid waste processing plant is more than constructing a building. The right equipment ensures smooth waste handling machinery operations, improves efficiency, and helps recover valuable materials from mixed waste. Without proper equipment planning, even well-designed plants can face delays, bottlenecks, and low output.

In this blog, we will cover the essential equipment required for a functional and efficient waste processing plant, keeping operational needs and long-term sustainability in mind.

Understanding the Role of Equipment in Waste Processing

A municipal waste processing plant manages the collection, segregation, and processing of mixed waste streams. The main purpose of the equipment is to:

Reduce manual handling

Improve segregation accuracy

Increase recycling and recovery rates

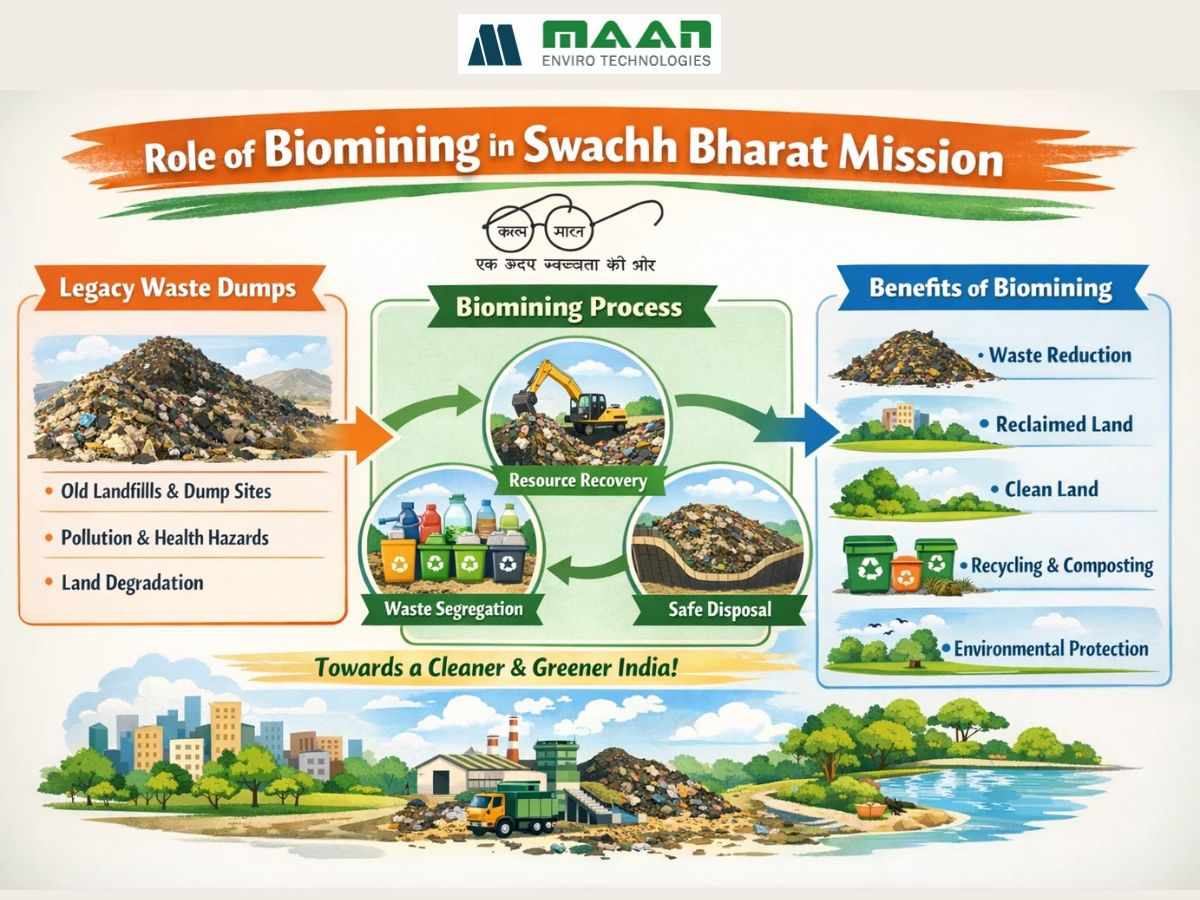

Reduce dependency on landfills

By integrating the right waste handling machinery, municipalities and industries can handle waste efficiently and sustainably.

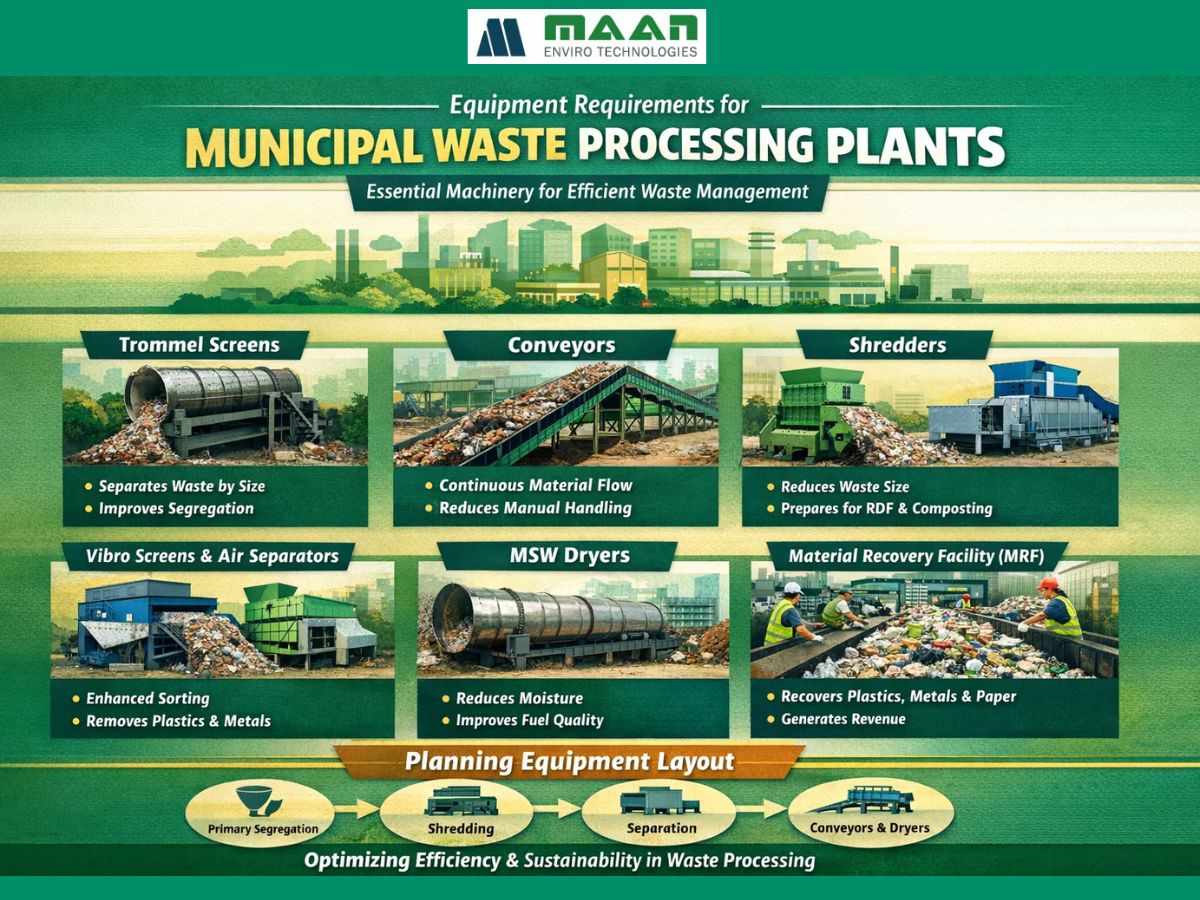

Key Equipment for Municipal Waste Processing Plants

Trommel Screens

Trommel screens are one of the most important machines in a waste processing plant. They separate waste based on size using a rotating drum with perforations.

Benefits

Early separation of fine and organic waste

Reduces load on shredders and downstream equipment

Improves quality of recyclables and compostable material

Trommel screens help maintain a steady flow of waste while improving overall segregation efficiency.

Conveyors

Conveyors connect various machines in the plant and move material continuously, reducing manual labour.

Why conveyors are essential

Maintains consistent material flow

Reduces spillage and mess

Improves overall plant safety

They act as the backbone of any municipal solid waste processing plant, ensuring smooth waste handling machinery operation.

Shredders

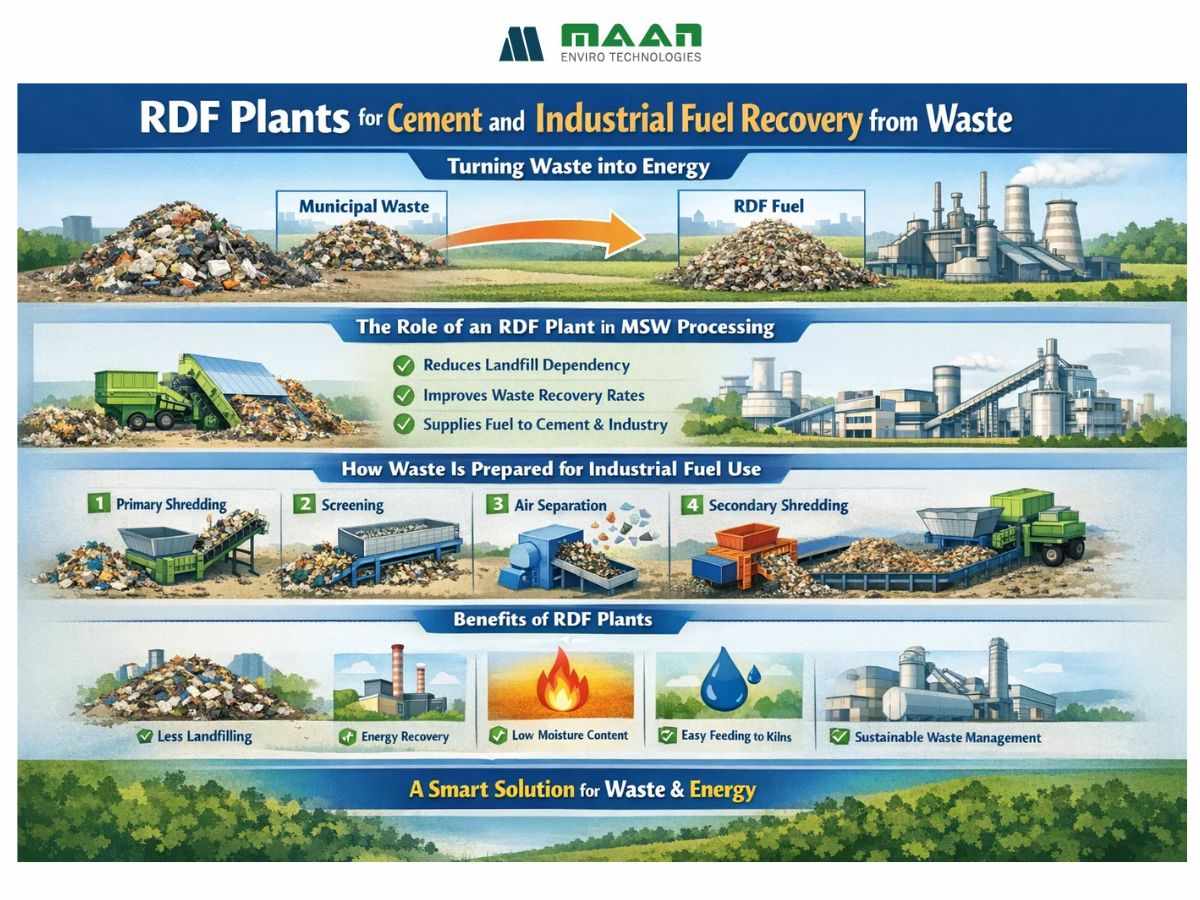

Shredders, including hammer shredders and M&J shredders, reduce waste size for easier handling.

Operational benefits

Uniform particle size for downstream processing

Better separation of recyclables

Prepares waste for RDF (Refuse-Derived Fuel) or composting

Proper shredding improves plant efficiency and reduces stress on other equipment.

Vibro Screens and Air Density Separators

These machines help refine waste segregation.

Vibro screens classify waste by size and remove grit and sand

Air density separators separate light materials like plastics from heavier items such as glass and metals

Using these machines increases the recovery rate of recyclables and reduces contamination in output streams.

MSW Dryers

Moisture content can affect processing efficiency. MSW dryers reduce moisture in organic waste, making it easier to handle and improving the quality of compost or RDF.

Advantages

Reduces odour

Enhances shredding and screening performance

Improves calorific value of waste for fuel production

Drying ensures smooth operation of other waste handling machinery.

Material Recovery Facility Technology

A modern municipal solid waste processing plant often integrates material recovery facility technology in India. MRF technology helps recover valuable materials such as plastics, metals, and paper, which can be sold or recycled.

Benefits of MRF technology in India

Reduces landfill load

Generates additional revenue from recyclables

Supports a circular economy

At the same time, understanding the benefits of MSW processing facilities in India helps municipalities and industries plan equipment layouts better. These benefits include higher recycling rates, reduced landfill dependency, improved operational efficiency, and long-term cost savings. Highlighting these advantages in the planning stage ensures the plant meets environmental and economic goals.

Planning Equipment Layout

Equipment selection is only part of the process. Proper layout and sequencing are equally important for plant efficiency. A typical flow in a municipal waste processing plant might include:

Primary segregation using trommel screens

Size reduction using shredders

Separation using air density separators and vibro screens

Conveyors connecting all units

Drying units for organic waste

Material Recovery Facility integration

A well-planned layout reduces bottlenecks, prevents downtime, and ensures all machines work in harmony.

Key Considerations for Choosing Equipment

When selecting waste handling machinery for a municipal solid waste processing plant, consider:

Daily waste volume

Composition of waste including wet, dry, bulky, or industrial

Space availability for equipment

Maintenance and operational support

Integration with Material Recovery Facility technology

Proper selection and planning lead to higher MSW efficiency and sustainable operations.

Conclusion

Setting up a municipal solid waste processing plant requires more than just land and labour. The right waste handling machinery, including trommel screens, conveyors, shredders, dryers, and MRF technology, is critical for efficient waste segregation, recycling, and processing.

By planning equipment selection and layout carefully, municipalities and industries in India can improve MSW efficiency, reduce environmental impact, and recover valuable materials. Understanding the benefits of MSW processing facilities in India ensures that the plant delivers both operational and environmental advantages. A well-equipped plant is the foundation for sustainable waste management and cleaner urban environments.

Write a comment ...