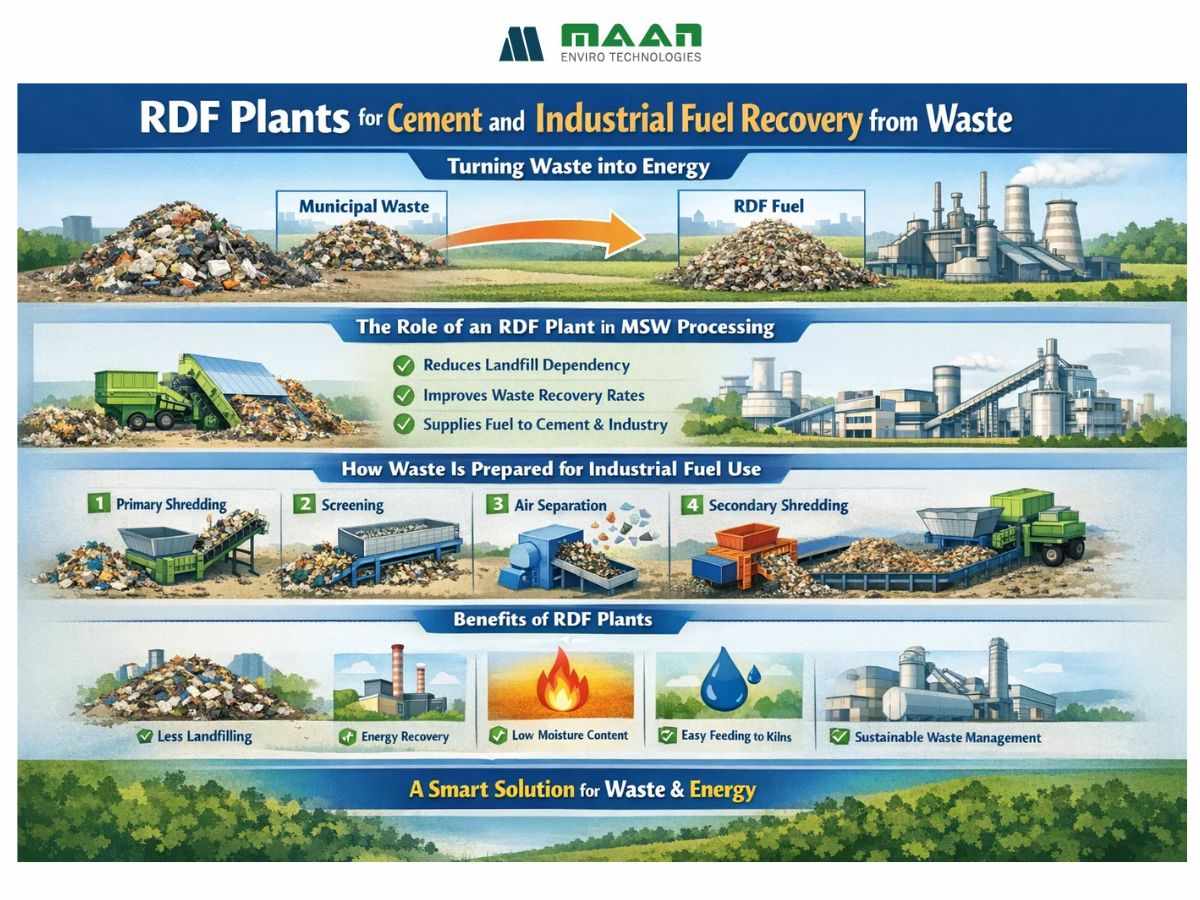

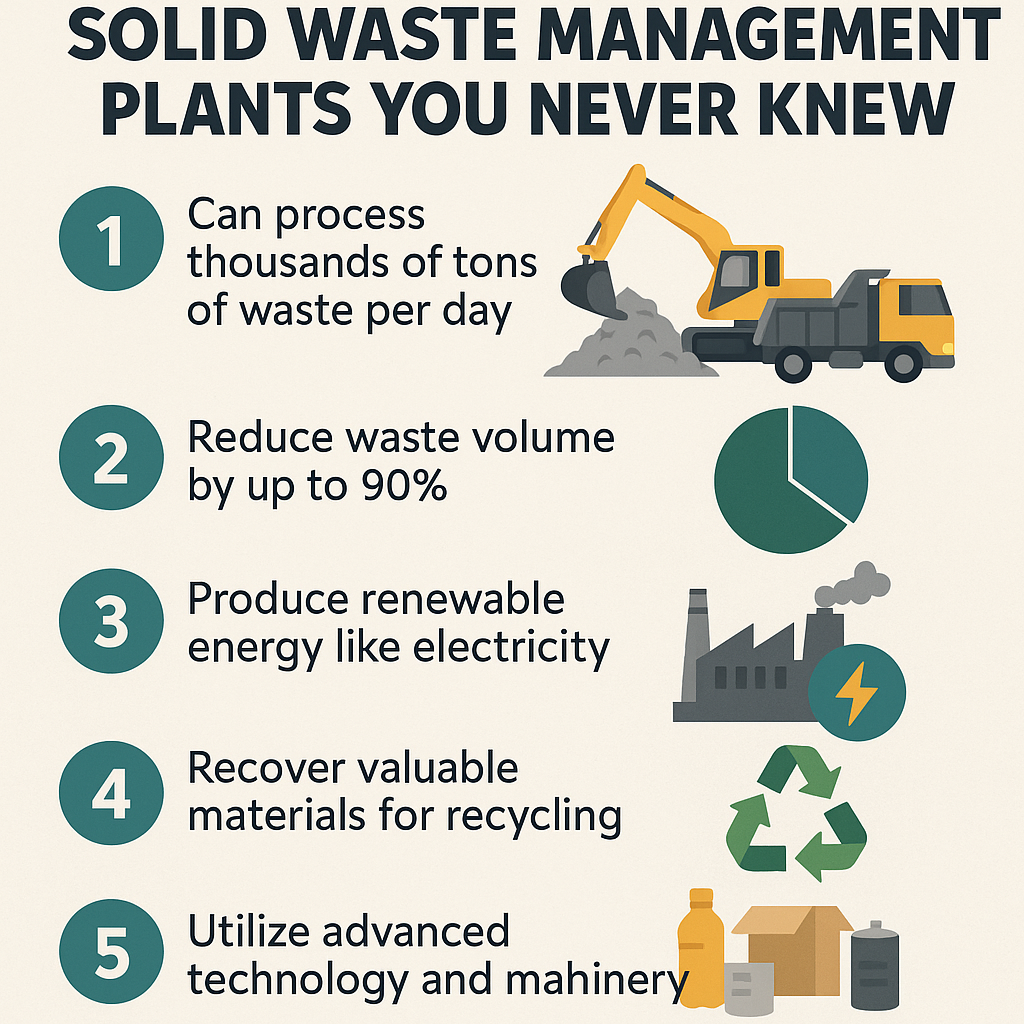

An RDF plant converts dry and high-calorific waste into fuel that can be used by cement plants and other industries. Instead of sending this waste to landfill, it is processed through a series of machines that improve fuel quality and make handling easier for industrial users.

This approach supports both waste reduction and energy recovery, which is why many municipal bodies now include RDF plants as part of their solid waste processing projects.

What Is the Role of an RDF Plant in MSW Processing

In municipal solid waste facilities, an RDF plant focuses on the dry fraction of waste such as plastics, paper, textiles, and packaging material. These materials have good burning value and are suitable for fuel use after proper processing.

By separating this fraction, the RDF plant helps:

reduce landfill dependency

improve overall waste recovery rates

supply fuel to cement kilns and boilers

This makes RDF plants a practical solution for cities dealing with high volumes of mixed waste.

How Waste Is Prepared for Industrial Fuel Use

Before waste becomes usable fuel, it goes through several steps inside the RDF plant:

primary shredding to reduce waste size

screening to remove soil and fine material

air separation to isolate light combustible waste

secondary shredding for uniform fuel size

These steps ensure that the final RDF is consistent and safe for industrial feeding systems.

For a simple explanation of the full process, you can also read how waste is turned into useful fuel through RDF processing.

Why Cement Plants Prefer RDF as an Alternative Fuel

Cement plants require steady and high-temperature combustion. RDF produced in a controlled RDF plant meets this need because it:

has stable calorific value

contains less moisture than raw waste

can be fed directly into kilns or preheaters

Using RDF also supports waste utilisation while reducing the use of coal and petcoke.

Planning an RDF Plant for Long Term Waste Management

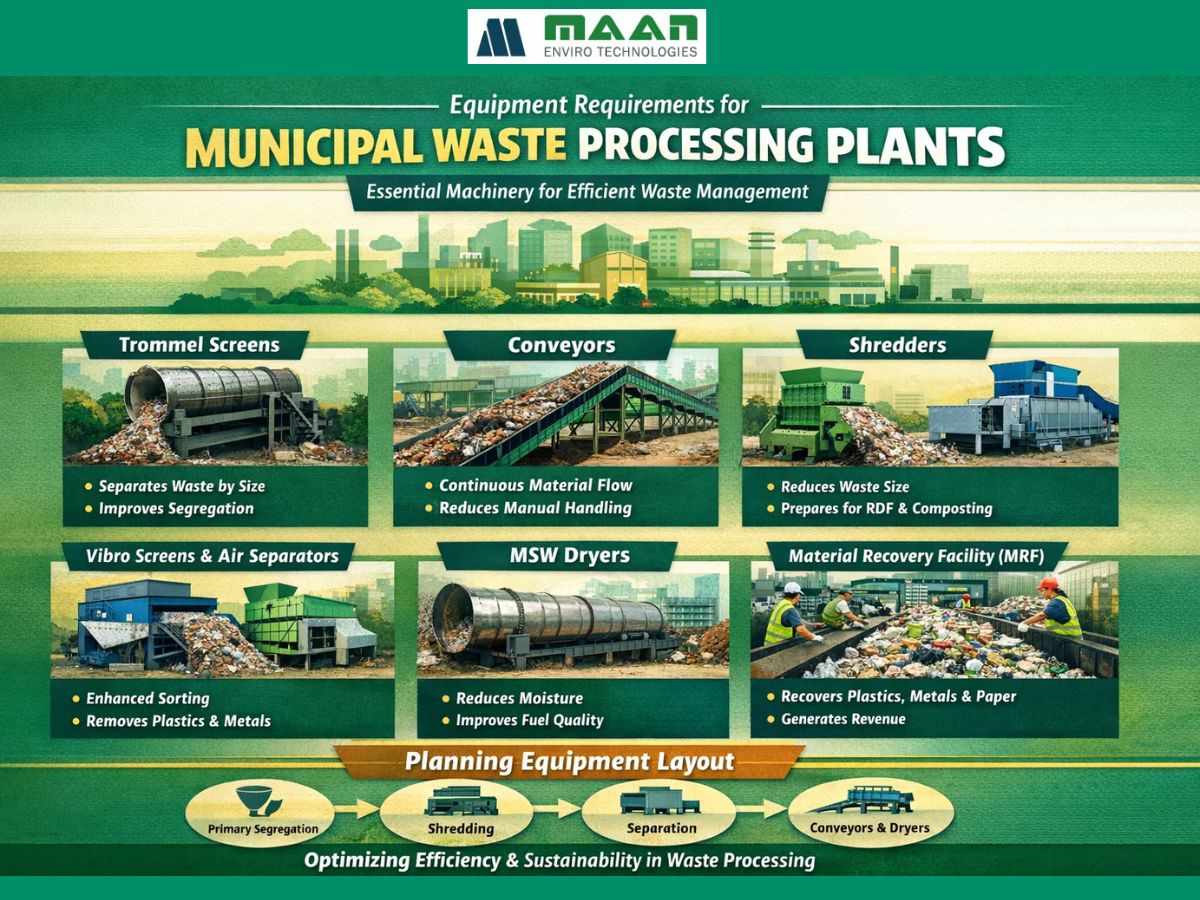

When planning an RDF plant, it is important to match equipment capacity with daily waste input and fuel demand from nearby industries. Good plant layout, proper segregation, and regular maintenance all help in keeping fuel quality stable.

RDF plants work best when they are part of a complete MSW processing system that also includes composting, MRF operations, and residue handling. This balanced approach helps cities manage waste in a more organised and long-term manner.

Write a comment ...